3D MILLING & PROTOTYPES

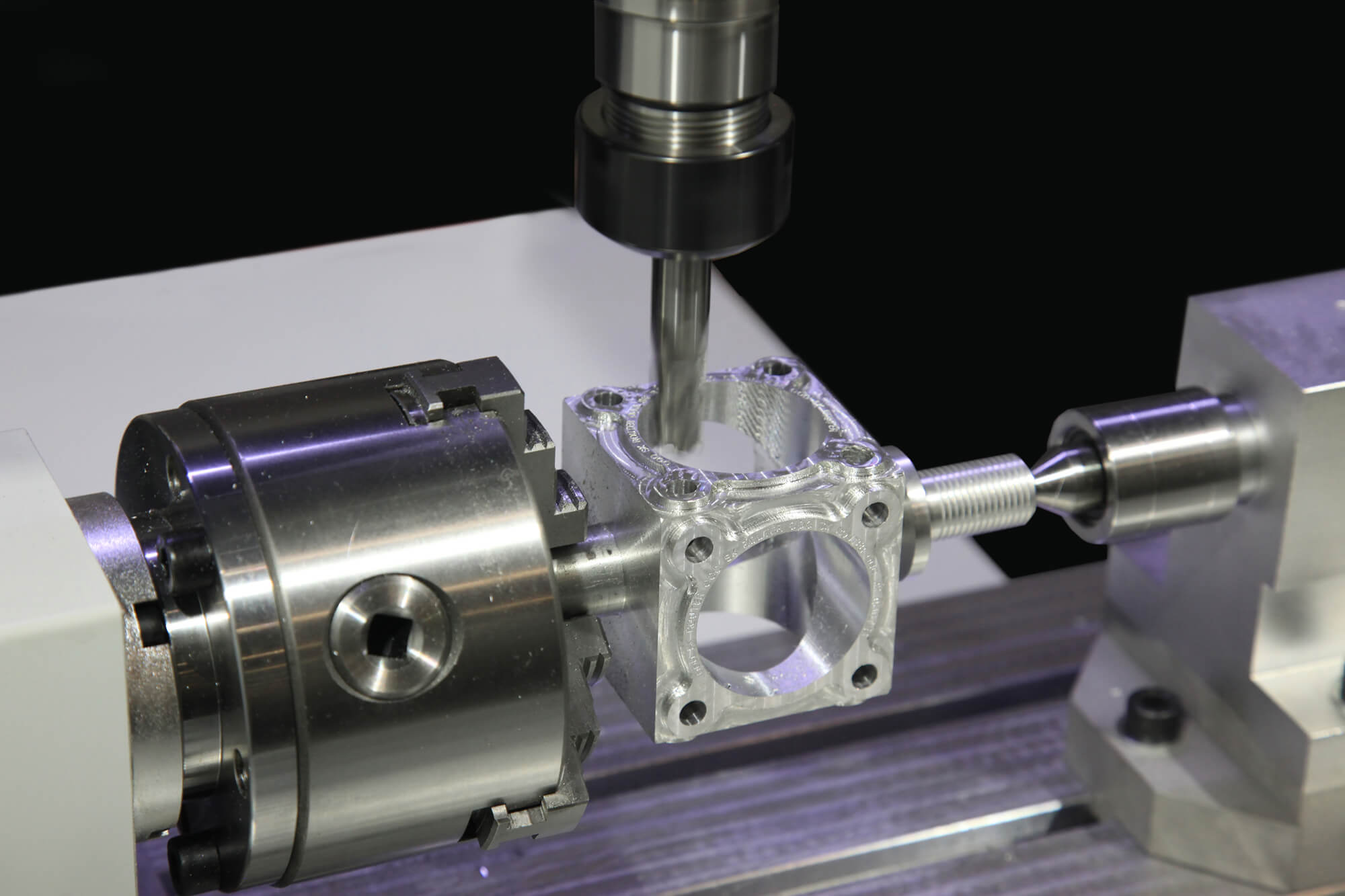

Suiting a wide variety of machining needs, Green Oak’s Vertical Machining Centers deliver high-quality 3D milled metal products in a quick and cost-efficient and manner. 3D milling is a subtractive process, meaning material is removed during milling. This involves utilizing rotary cutters to shave metal off of a workpiece. Vertical machining uses a vertically oriented spindle with the tools pointing directly down from the tool holder.

At Green Oak Tool & Services, we specialize in 3D milling aluminum and steel. Our high-speed CNC machining centers are capable of milling steel or aluminum parts to tight tolerances and precise specifications. Our team of well-trained and highly-experienced 3D milling specialists is dedicated to precision, quality, and efficiency. In tandem with the advanced equipment we possess at Green Oak, our expert team is able to both meet and exceed your 3D milling expectations.

Engineering Phase

In some cases, our customers have the ability to design their models for us to use in the 3D milling process. The customer will provide the model, and we create the 3D item for them. Alternatively, a customer may not have the ability to design the product but knows the specifications. We can create a model for you that is exact in every detail. We utilize CAD to create drawings and models for your project.

Programming

We utilize the latest software to program our 3D parts. We can import multiple file types. If you have a 3D model, we can upload it from your program file. Our experienced programmers can also create quality models from scratch. Once we have a model, we create the advanced 3D Milling programs for our machines.

3D Milling Process

Green Oak Tool staff can create highly precise designs. We use our machines to create detailed 3D parts. All of our tooling and mold machines provide exemplary quality finishes on 3D shapes. The process is one of precision, quality, and reliability. The final products will meet the distinct specifications required by each customer. As technology improves, so do our processes. So our machines are always capable of producing top-of-the-line products.

Green Oak Tool