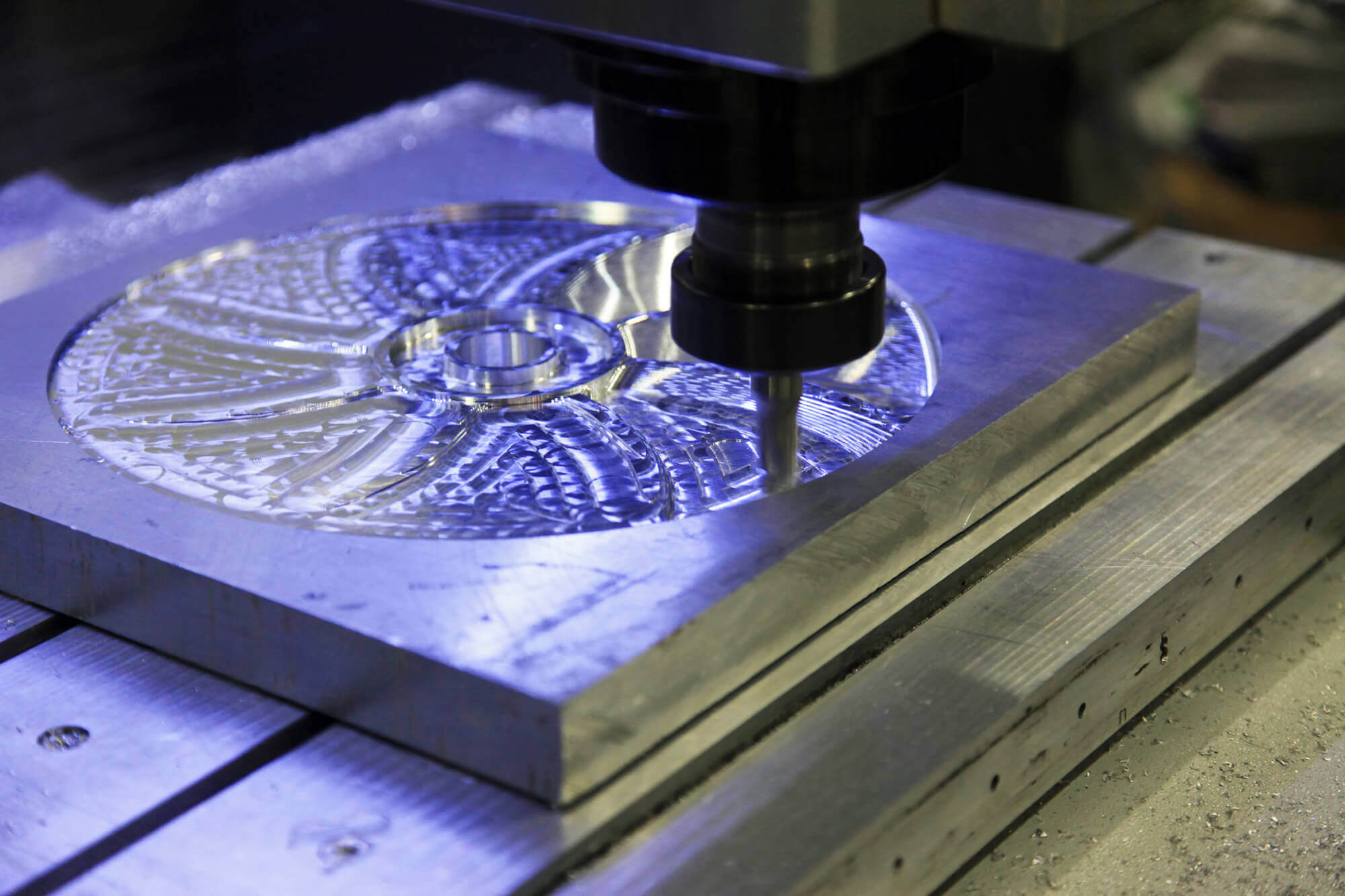

PROTOTYPING – Prototype Molds

Green Oak Tool produces high precision prototypes and aluminum and steel molds. Our experienced team along with advanced manufacturing equipment can meet your prototype needs. We support you through every stage of the prototype process: idea development, form concept, pre-production, and volume production. We can bring your concept form to market quickly, whether single part or multiple and large complex components.

Rapid prototype services, high precision tolerances, and fast turnaround times. Our high precision prototype tolerances provide accuracy in cavity detail, and will meet your production tooling requirements. Our priorities are accuracy and quality, whether you require a stand-alone tool or a single cavity insert. We also specialize in Master Unit Die Molds and Standalone Molds.

Green Oak Tool has the machinery and services necessary to complete your prototype project.

-

Our equipment can perform multiple operations and minimize the turnaround time.

-

We provide cost effective prototypes and prototype molds.

-

Master unit die molds can lower costs and reduce turnaround time for prototype revisions.

-

Inserts can be removed, redesigned, and re-inserted while leaving the larger part of the tool in the injection mold machine.

Quality Processes

Once we receive a CAD drawing of your design, we immediately produce the die and punch to bring the part to reality. Tight tolerances are adhered to for low and high volume production runs. Our ability to manufacture prototype molds, punches, and dies allows our clients to rapidly test and review their product designs, significantly decreasing the time it takes to put it into full production. We maintain complete in-house processes for our high quality standards. Quality is integrated into every prototype we produce.

We also offer custom manufacturing services with a variety of technologies such as:

Green Oak Tool Prototype Advantages

-

Collaboration to manufacture a prototype in the fastest and most cost-effective ways, and realize concepts into visual parts.

-

Taking the prototype concepts, images and ideas form 2D visions into real products. You’ll be able to show a physical model to your clients, collaborators, customers and investors.

-

Finish design testing and refining of your prototype concept. We can detect design flaws and eliminate costly redesign with close physical observation. And we can improve your product design before mass production.

-

We can offer variations to test your prototype before mass production. We can also recommend production adjustments for further improvement. Multiple versions can be created, with differing surface textures and finishing processes, offering you more options.

-

We can improve and streamline the production process by comparing different prototypes with various producing technologies and materials.

-

Save time and reduce costs by eliminating equipment setup and tooling preparation.

Green Oak Tool